Call Us +44 (0)1686 611200

Proudly Made in the United Kingdom

Our Top 5 Forklift Attachment Picks for the Food and Drink Industry

By Jason Cadman on August 17, 2022

Working in the food and drink industry can come with a whole host of challenges – not only have you got to think about the best equipment for your material handling needs, but any equipment you do use must also be suitable for the highly regulated environment in which they operate in. In this blog, we share our top five forklift attachment picks for those operating in the food and drink industry.

Common Issues

Food and drink is one of the most tightly regulated, monitored environments in which to work – considering the health, safety, cross-contamination risks and cleanliness of the site and all of its equipment and machinery.

That’s why, when choosing a forklift attachment, you must consider the environment in which they are to operate in to ensure they’re fit for purpose, but above all, safe.

Cross-Contamination

Corrosion can lead to cross-contamination due to surface pitting and damage. Where it’s essential to minimise corrosion, stainless steel forklift attachments would have the advantage over regular steel due to their non-corrosive and pitting resistance properties, as well as their suitability for pressure washing or steam cleaning.

Allergies

Contamination can be a particularly dangerous problem in the food and drink industry when you consider the potentially life-threatening impact of cross-contamination to people suffering from food allergies, making the use of stainless steel attachments, particularly important – they can be cleaned with ease, won’t corrode, and can last years if maintained properly.

Odours

It’s inevitable that food waste will begin to rot and thereafter emit unpleasant odours into a working environment / attract unwanted flies etc. Keeping these odours to a minimum should be a priority when choosing suitable waste handling equipment.

Top Five Forklift Attachments to Help Combat these Issues

Our portfolio of forklift attachments for the food and drink industry range from forklift drum lifters and forklift drum rotators and tippers, to forklift tipping skips and tipping bins for convenient waste disposal. Here, we’ve cherry-picked our top five products for the food and drink industry, and break down how each one can provide a safe, clean, and durable solution to a variety of material handling needs.

#1 Lidded Tipping Skip

Similar to our standard range of forklift tipping skip attachments, this specific model comes with a fully fitted hinged lid which eliminates the possibility of skip rubbish being blown out and keeps the working area clean and contamination free. It also provides a useful barrier against skip odours which can be common in the food and drink industry.

The lid of this tipping skip can also be locked when closed if required, and waste and debris can be easily collected and disposed of by folding the lid back over the rear portion.

Manufactured with a regular duty 3mm thick steel body and a heavy-duty underframe, they can also come in a variety of colours to aid waste segregation, meaning our lidded forklift tipping skips are ideally suited for the collection and disposal of food waste and rubbish.

#2 Stainless Steel Barrel Grab

Manufactured entirely from stainless steel, this high-quality yet lightweight forklift barrel grab is ideal for use in the food and drink industry where rust contamination can cause a problem.

The adjustable function on the drum grab means that both 210 litre steel drums and 210 litre ‘L’ and ‘XL’ ring plastic drums can be handled safely, and the simple design of this barrel grab with few moving parts means maintenance and servicing costs are kept to a minimum, whilst the fully automatic operation reduces time and labour costs as there is no need to leave the forklift cab during use.

Compatible with most fork lift trucks on the market due to the generously sized fork pockets, which also make it quick and easy to attach, this is a versatile piece of equipment for the various handling needs of this industry.

#3 Forklift Drum Rotator

Our forklift drum rotator is perfect for the safe and controlled handling and pouring of drum contents. With a high-quality gearbox connected to a crank handle offering up to shoulder height rotation, drums can be rotated up to 360 degrees with minimal effort making it the ideal attachment for the drum de-canting requirements of the food and drink industry.

As with our stainless steel barrel grab, this attachment is also designed to suit the two most popular drum sizes on the market.

#4 Stainless Steel Dual Drum Grip

Being manufactured entirely from stainless steel makes this drum grip is ideal for use in the food and drink industry.

It has the capability of handling two steel or plastic drums at the same time, and a strong ‘parrot beak’ mechanism reduces drum damage whilst also reducing costly spillages, which could prove dangerous or at the very least present contamination problems.

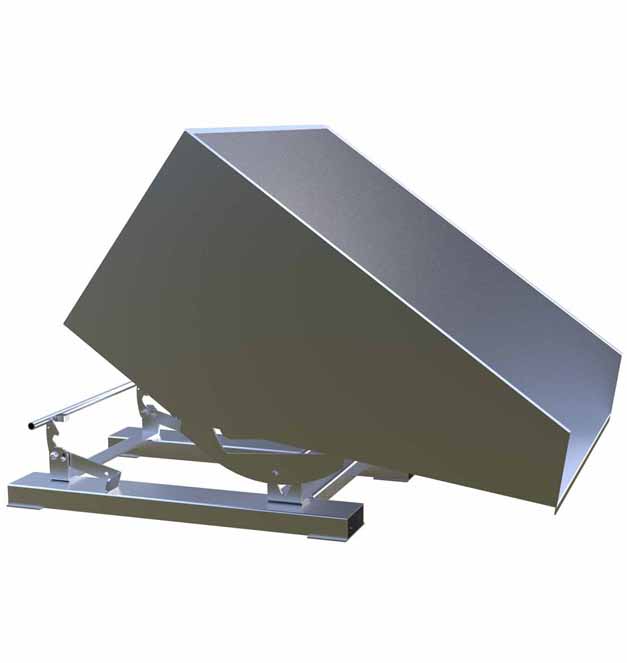

#5 Stainless Steel Tipping Bins

Our range of fully stainless steel forklift tipping bins are designed for use primarily in the food and drinks industry, where corrosion resistance and the minimisation of contamination is vital.

Every part of the tipping bin is manufactured from stainless steel, which makes it particularly effective where pressure washing and steam cleaning are necessary.

The design features full-width release handles and a twin locking mechanism for added safety, whilst pre-drilled castor plates and a bolted tipping handle mean no welding is required on-site to reduce contamination risk.

Conclusion

The food and drink industry does face its own challenges when it comes to its material handling requirements. However stainless steel forklift attachments, such as forks, drum handlers, fork extensions and tipping skips, are not only highly valued in the forklift industry as a whole for their superior quality and durability, but they can be especially useful to help reduce contamination risk