Call Us +44 (0)1686 611200

Proudly Made in the United Kingdom

One Size Doesn’t Fit All

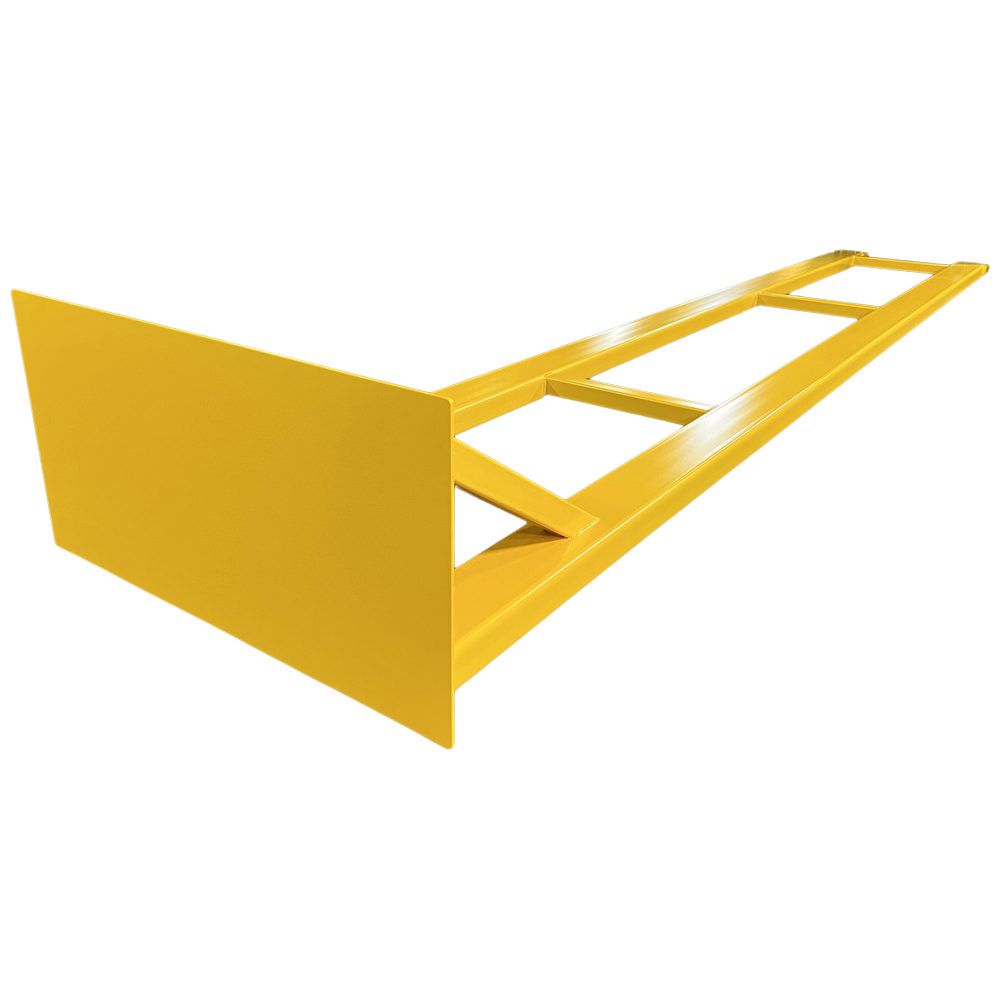

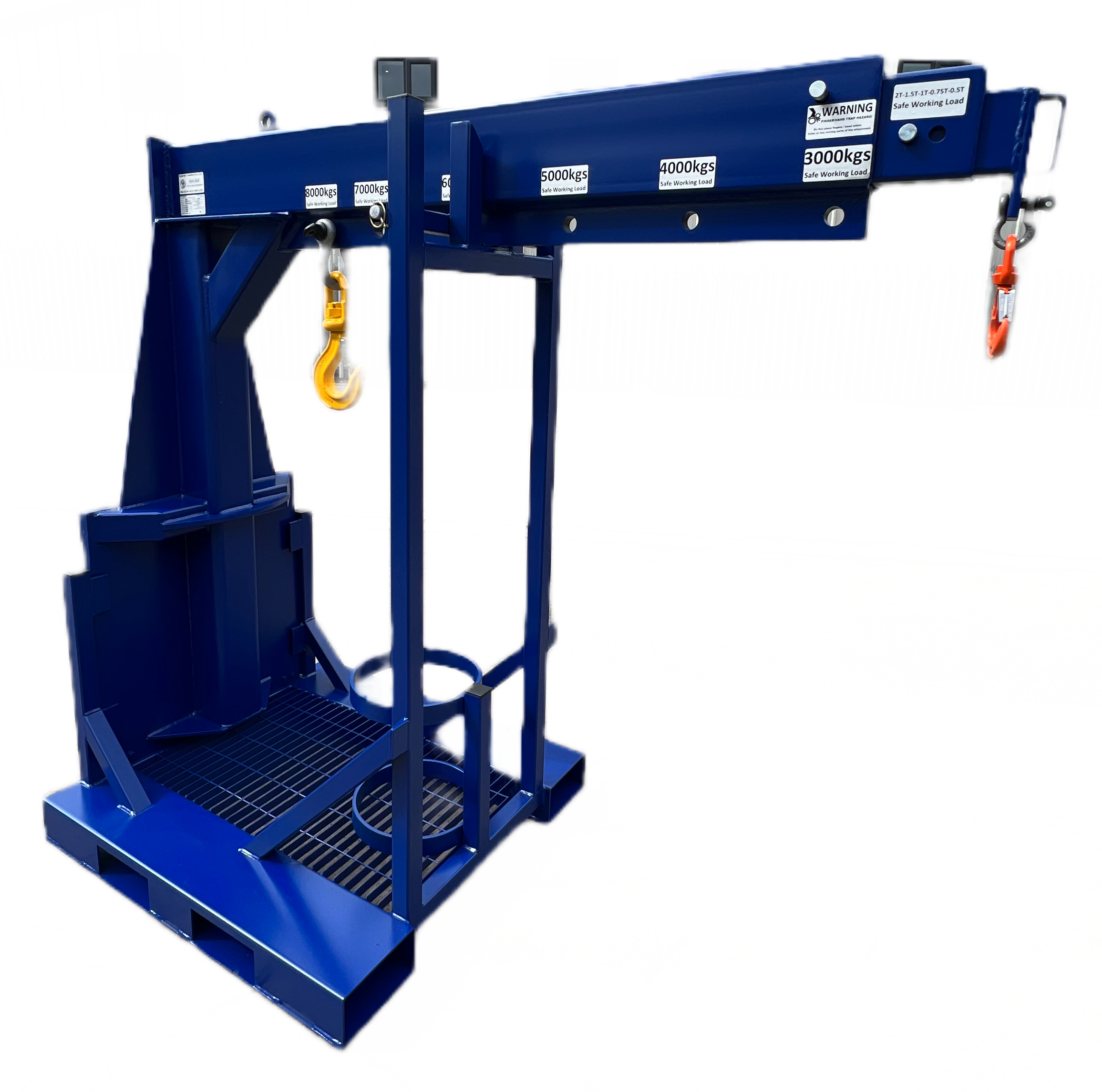

If you can’t find an existing attachment or a solution to your material handling problem within our standard range of equipment, then don’t worry, as we also offer a state-of-the-art custom design service where we can tailor design a product, utilising the latest design techniques to specifically suit your handling requirements. We’re aware that ‘one size doesn’t fit all’, and our custom service aims to solve your material handling issue to ensure you obtain the perfect solution without wasting money and resources purchasing ‘from the shelf'.

Our Expertise

With a dedicated design department and over 100 years of combined engineering experience, we’re confident that we can offer fresh and innovative solutions to any material handling problem. Our technical design team will work closely with you to understand your specific requirements to ensure you receive a first-class product that meets and exceeds your expectations. And with an on-site consultation service available, our technical team is also always available to offer advice and guidance on any Health & Safety Legislation relevant to your requirements.

Our Process

Utilising the latest SolidWorks design technology, our design team can work closely with you to design your perfect handling product. During our concept development process, we use CAD software to produce a selection of photo-realistic images and animations to ensure our design concept is completely in-sync with your custom specifications. Our customer approval process provides you with the opportunity to see the ‘finished’ product prior to manufacture and gives you the opportunity to make any changes you see fit.

All of our custom design solutions are tested for strength and safety, and the results are fully stress-analyzed to ensure complete safety and compatibility prior to manufacturing. When your custom-designed attachment is delivered, you can rest safe in the full knowledge that your unit has been fully tested and certified to comply with the current Health & Safety Regulations.

It’s What Makes Us The Best

- Dedicated design department utilising SolidWorks (3D CAD)

- Combined with over 100 years of engineering experience ensures that you’re in the safest of hands

- Proven Customer Approval Process

- Products can be tested for strength and safety, and the results fully-analysed

- Technical Team always available via phone for advice and guidance around both health and safety/legislation and handling problems

- Studies simulate the real-world performance of solid, thin-walled, and structural features.