Call Us +44 (0)1686 611200

Proudly Made in the United Kingdom

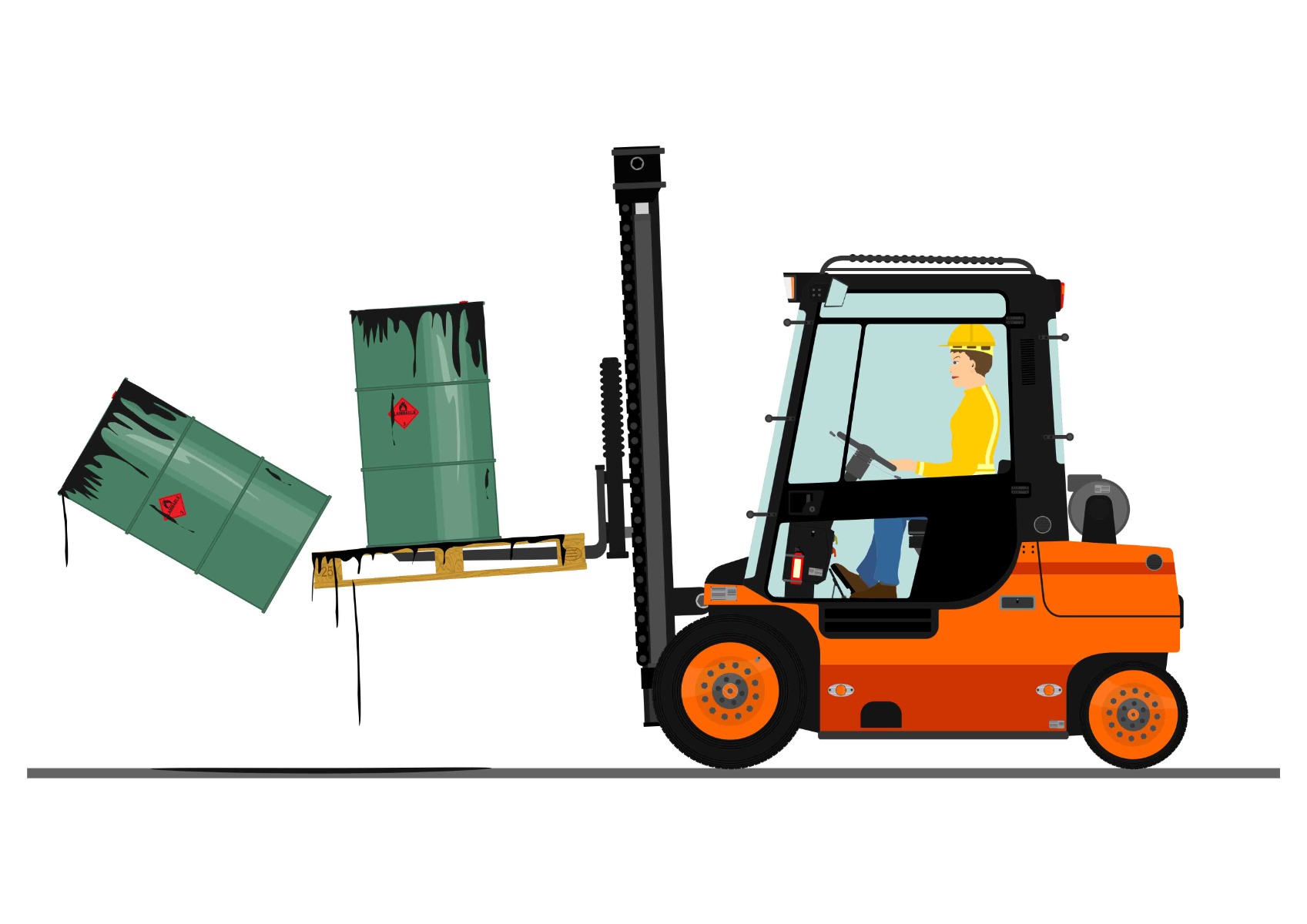

What You Should Know About Forklift Attachment Safety

By Jason Cadman on October 26, 2022

Forklift attachments can be a real asset to a business. There is no doubt that used properly they can boost the efficiency of your operations. There are a multitude of different forklift attachments on the market, such as drum handlers for handling and pouring from large drums, tipping skips for waste collection, forklift sweepers to make light work of yard cleaning, and even forklift platforms to allow personnel to work safely at height. But using such versatile pieces of equipment is not without its associated risks. Here we explore forklift attachment safety to ensure you are getting the most from your investment.

What Are The Risks Associated With Using Forklift Attachments?

There is a very real risk of serious injury to both forklift operators and pedestrians whilst using forklift attachments when;

(1) A Risk Assessment Has Not Being Carried Out

In every case, a proper risk assessment should be carried out to ensure the suitability of any new forklift attachment for its intended purpose.

Taking, for example, a four-fork attachment which is designed for the safe handling of wide unstable loads. Whilst it can reduce the associated risks of doing just that, when an uneven surface is introduced, this can cause the product to slide off the attachment. It’s important to fully consider not only the intended task but also the environment within which the attachment will operate.

(2) There’s a Lack of Understanding about How an Attachment Can Affect a Forklift’s Operation

An attachment can alter how a forklift truck operates, so it’s important to consider this for both safe and efficient use. For example, when selecting a lifting jib attachment, where there is potential for a ‘swinging’ load and movement of the attachment, a ‘fixed length’ design is best. Wide carriage backplates can reduce sideways movement to offer a safe, stable load lifting option, reducing damage from loads swinging excessively.

(3) Failure to Understand How the Forklift Attachment Can Impact the Forklift’s Lifting Capacity

It’s never a good idea to overload the lifting capacity of your host truck. But if the forklift attachment is rated with a higher lifting capacity than a truck can handle, it can become especially dangerous. Give careful consideration to the capacity ratings to avoid both safety risks and unnecessary wear and tear.

(4) Using an Inappropriate Forklift Attachment for the Task At Hand

Using an attachment that is not fit for purpose can prove inefficient, damaged goods, or worse still, be dangerous. One does still hear of catastrophic consequences when personnel have been lifted for working at height using inappropriate equipment, such as a pallet or even just forks.

With such a wide range of attachments available there really is no excuse, and, with a little forethought, you can ensure your attachments are not only absolutely safe but also appropriate, keeping you running at your most efficient.

Safety Factors to Take Into Consideration When Using Forklift Attachments

There are many factors to consider in the smooth and safe operating of forklift attachments, such as;

(1) Are The Manufacturer's Operating Instructions Being Followed?

Pay attention specifically to things like load capacity and de-rated load capacity. The Safe Working Load of the forklift attachment should be clearly labelled and identified on the product at all times.

(2) Make Sure the Attachment Is Correctly Matched To the Forklift

With the majority of forklift attachments being of the fork-mounted variety, it’s important to ensure the sizing of the attachment fits that of the forklift truck. Using fork pockets that are too large could compromise any securing methods and pose a safety risk.

(3) Has The Operator Been Adequately Trained In Using The Attachment?

It is imperative that the operator is adequately trained in both the safe securing and operation of the attachment. Proper training should be provided before use, and should be updated where necessary.

(4) Is The Attachment Properly Rated?

Ensure the forklift attachment is properly rated, paying close attention to how this affects your forklift truck’s safe handling capacity. This is known as the ‘De-Rated’ capacity and is affected by many factors such as the weight of the attachment, combined with the weight of the product to be handled, and the distance from the attachment to the forklift truck.

(5) Is The Correct Forklift Attachment Being Used For The Task?

Never ‘make do’ with an attachment that is not specifically designed for the material handling task at hand. Not only can this cause damage or potentially render insurance invalid, but it can also prove dangerous.

(6) Has The Attachment Undergone Its Thorough Examination?

Under LOLER 98 and PUWER 98, it is your legal responsibility to ensure that your forklift attachments undergo a periodic Thorough Examination. Not only will having these inspections carried out ensure you remain compliant, but more importantly, they will ensure your forklift attachments remain safe and fit for purpose.