Call Us +44 (0)1686 611200

Proudly Made in the United Kingdom

What to Consider When Buying a Forklift Lifting Jib

By Clear Admin on May 16, 2022

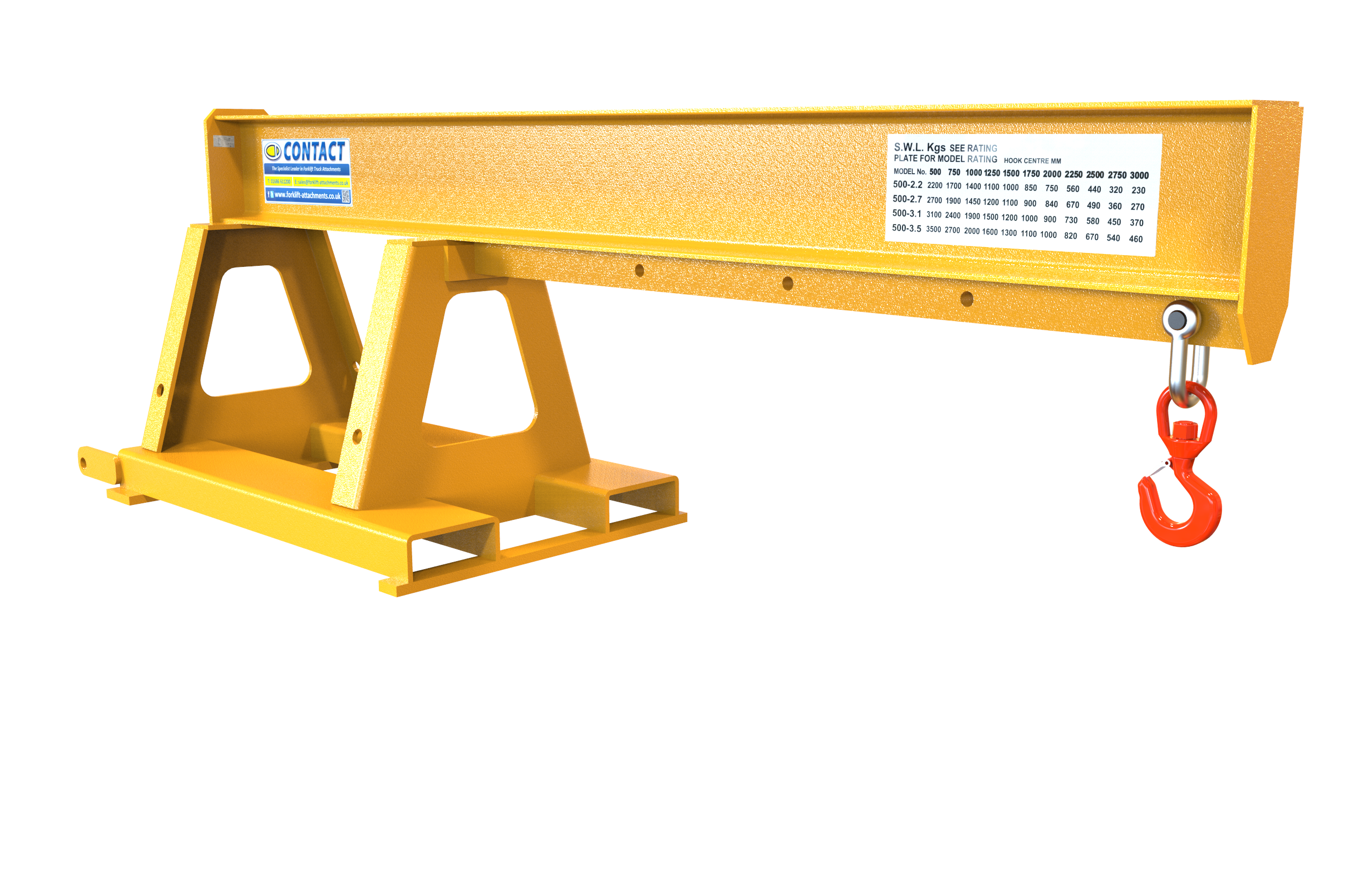

When it comes to buying a forklift jib attachment, it pays to know that they aren’t one-size-fits all. In this blog, we break down how lifting jibs can be used and mounted, share guidance on load and capacity, and provide our industry insight to help you get the most from this versatile piece of equipment

A forklift lifting jib attachment can help you to transform your existing forklift truck into a mobile crane within just a matter of minutes. A hugely popular piece of equipment for the construction industry, the attachment can help to safely lift and move heavy objects and loads.

A forklift lifting jib attachment can help you to transform your existing forklift truck into a mobile crane within just a matter of minutes. A hugely popular piece of equipment for the construction industry, the attachment can help to safely lift and move heavy objects and loads.

What Is The Capacity Of The Forklift Jib?

It’s never a good idea to overload the lifting capacity of the host truck (your forklift truck), and if the jib attachment is rated with a higher lifting capacity than a truck can handle, it can become especially dangerous. Careful consideration of these capacity ratings will enable you to make a decision about which lifting jib is right for you and your needs, provide peace of mind that it will be operated safely and as intended, and that you don’t cause unnecessary wear and tear of the forklift truck.

How Is The Forklift Jib Mounted to the Fork Truck?

Which jib attachment best suits your needs will depend on the type and frequency of your lifting tasks;

Fork Mounted

Fork mounted jibs allow for quick changeover when switching from forklift forks to forklift jib, as they feature large fork pockets which enable an instant ‘drive in’ fitting. They can be easily fitted by one person and safely and securely fastened to the forks with heel retaining pins, making them great for occasional lifting tasks.

Carriage Mounted

Forklift carriage mounted jibs are perfect for when continual load lifting is required. Mounting directly onto the forklift carriage, the forklift can be positioned closer to the load, converting your forklift truck into a more dedicated and heavier-use lifting crane. They come in a range of sizes and options from fixed length to telescopic reach, and standard height or high lift options for stacking.

Adjustable Vs Fixed Forklift Jibs

If your lifting tasks are repetitive and adjustments to the length of the jib are not necessary, then a fixed lifting jib would suffice. An adjustable forklift jib is more suitable for varied lifting tasks, as the length can be extended on a telescopic design to accommodate different load sizes, as well as raised or lowered into different positions. But it’s important to bear in mind that these adjustments will also affect the safe lifting capacity and stability of the jib.

What Type Of Load Will Be Handled By The Forklift Jib?

Which lifting jib to choose will depend on the type of load you want to lift;

Static Vs Swinging Load

Where there is potential for a ‘swinging’ load and movement of the attachment, a ‘fixed length’ design is best. Wide carriage backplates can reduce sideways movement to offer a safe, stable load lifting option, reducing damage from loads swinging excessively.

Load Distance

The distance the lifting jib sits away from your forklift, known as the ‘load centre’, coupled with the combined weight of the lifting jib and its load, could greatly affect your forklift’s ‘de-rated’ capacity.

Common Mistakes to Avoid When Using a Forklift Jib

Overloading: You should always ensure the forklift jib lifting capacity does not exceed what your host truck can handle – not only because it will cause excessive wear and tear to the forklift and potentially damage products, but it potentially be very dangerous to employees and those around the machinery.

Instability: Always make sure that your forklift truck is operating on level ground when using a lifting jib. Forklift jibs are only designed to be used in this way, and if they are used on an incline, it can impact the stability of the forklift truck. It’s also important to be mindful that a forklift truck can tip over if the forklift tines are pointing downwards whilst a lifting jib is in use.

Insecure Fitting: Lastly, ensure the lifting jib is securely attached to the forklift tines or carriage, using the heel retaining pins or carriage blocks supplied.

Frequently Asked Questions about Forklift Jibs

What Is a Jib Attachment?

A jib attachment can be added to your existing forklift to expand its lifting capabilities. Loads safely hang from the existing forklift tines, giving a fast and cost effective solution for carrying out a wide range of lifting jobs without the need to buy and store separate machinery such as cranes or hoists.

What Other Names Are Forklift Jibs Referred To As?

Forklift lifting jibs are sometimes known as forklift crane jibs, jib arms, forklift hook attachments, or lifting beams.

Why Does a Forklift Jib Attachment Affect Your Forklift?

Using a forklift jib attachment can affect the safe lifting capacity, and centre of gravity and therefore stability of your forklift, so it’s important to consider these factors and ensure you remain with safe working limits.

Conclusion

Whatever your lifting needs, our comprehensive range of forklift jibs and crane arms have been designed to effortlessly transform your existing forklift truck within a matter of minutes – enabling you to safely and efficiently carry out lifting tasks.