Call Us +44 (0)1686 611200

Proudly Made in the United Kingdom

Stainless Steel Forklift Attachments – When Do You Need Them?

By Clear Admin on June 16, 2022

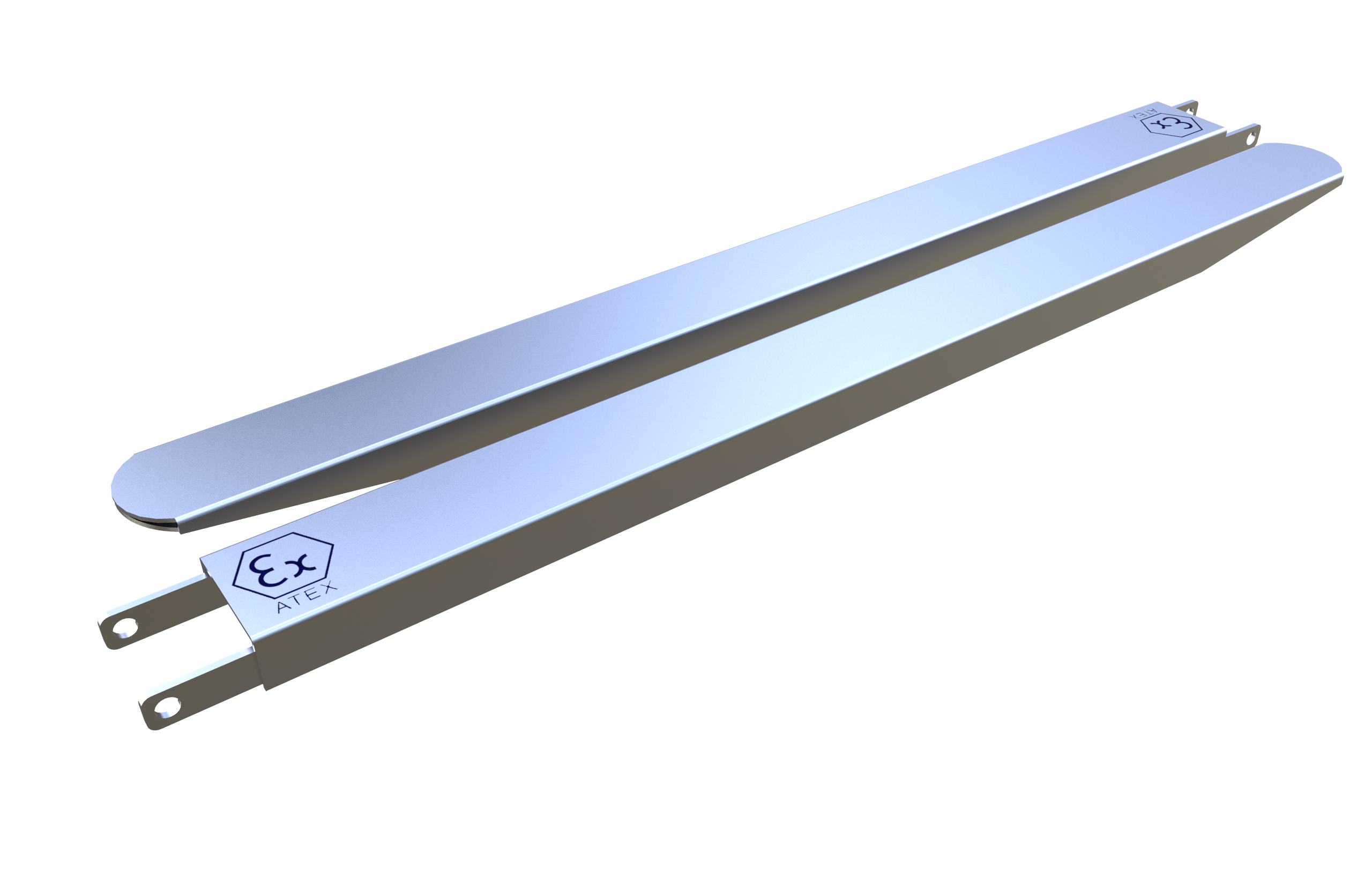

Stainless steel forklift attachments such as forks, drum handlers, fork extensions and tipping skips, are all highly valued in the forklift industry, especially for their superior quality and durability. There’s so much more to stainless steel than its longevity and shiny finish – get a primer on them by understanding when, why, and how they should be used.

There are many climate conditions or geographical locations where a standard forklift attachment just isn’t suitable. It could be in potentially hazardous or explosive environments, in the food and drink industry where cross-contamination is an issue, or it could be in the environment it’s used such as near seawater, which can corrode equipment quicker.

Corrosive Environments

Some working environments are naturally exposed to corrosive atmospheres, such as harsher locations where there is regular exposure to seawater. Due to its unique anti-corrosive properties, stainless steel would be the best option for forklift attachments in these areas.

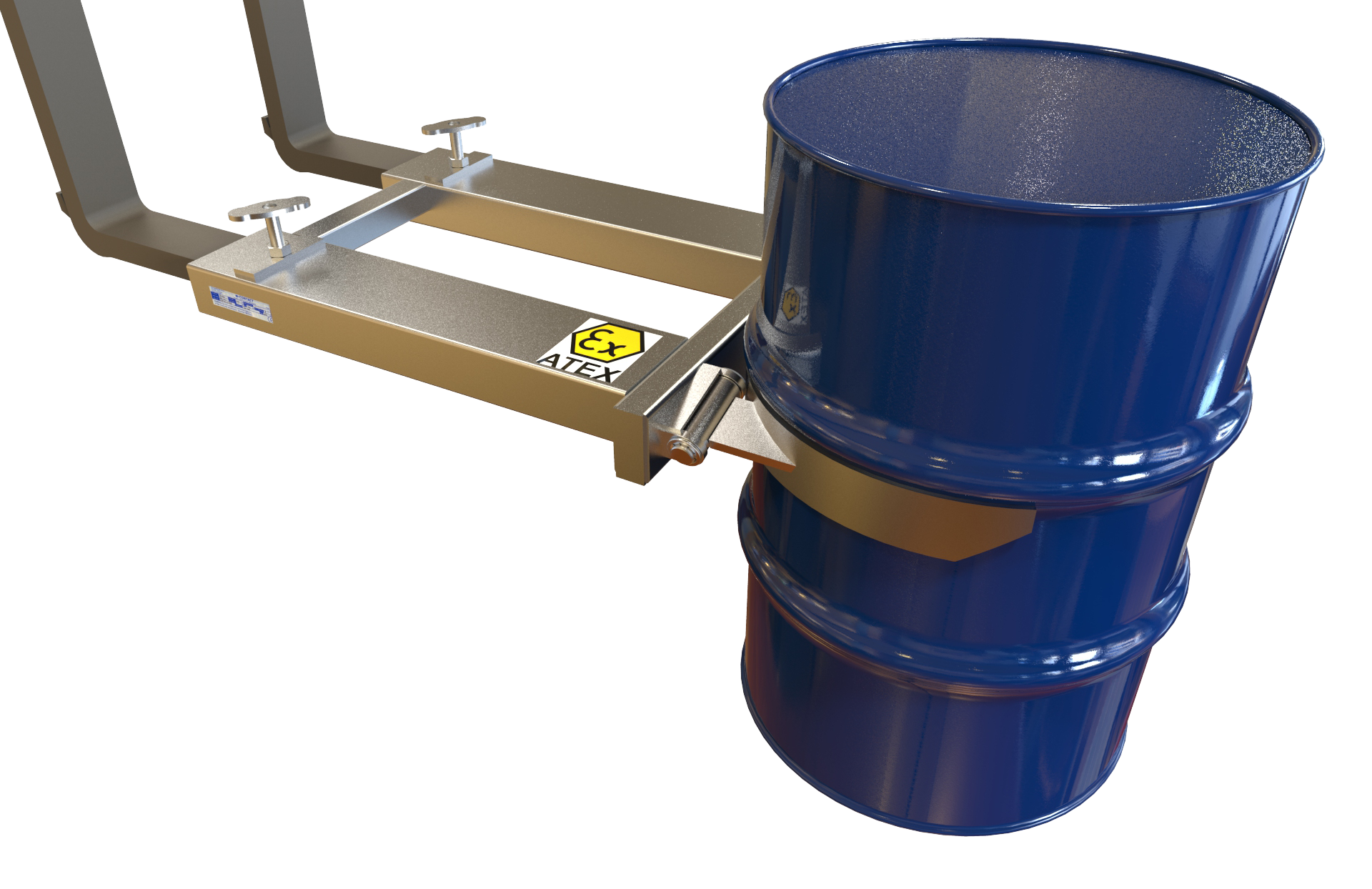

Hazardous or Explosive Environments

A potentially hazardous or explosive environment can include the presence of a mix of flammable gases in the atmosphere, which can cause a fire or explosion if a metal-to-metal spark is generated. These risks can be mitigated when using forklift attachments manufactured from stainless steel, due to its anti-sparking properties. Our range of stainless steel attachments come ATEX certified for complete compliance with the EU directive 94/9/EC, making them suitable for Zone 1 and Zone 2 hazardous working areas.

A potentially hazardous or explosive environment can include the presence of a mix of flammable gases in the atmosphere, which can cause a fire or explosion if a metal-to-metal spark is generated. These risks can be mitigated when using forklift attachments manufactured from stainless steel, due to its anti-sparking properties. Our range of stainless steel attachments come ATEX certified for complete compliance with the EU directive 94/9/EC, making them suitable for Zone 1 and Zone 2 hazardous working areas.

Cross-Contamination or Hazardous Liquids

When used in the food and drink industry, where minimisation of contamination is essential, stainless steel forklift attachments would have the advantage over regular steel due to their non-corrosive and pitting resistance properties, as well as their suitability for pressure washing or steam cleaning. In the chemical industry where hazardous liquid may need moving or lifting, it may also be necessary to use stainless steel attachments, such as drum lifters, because the anti-sparking properties of stainless steel help to reduce the risk of a chemical explosion.

The Benefits Of Stainless Steel Forklift Attachments

Stainless steel forklift attachments feature many benefits over standard steel, and although the purchase cost is greater, some of those benefits are non-negotiable in certain environments. Consider the varied properties of stainless steel, and whether they are critical to the environment in which you are intending to work;

Stainless steel forklift attachments feature many benefits over standard steel, and although the purchase cost is greater, some of those benefits are non-negotiable in certain environments. Consider the varied properties of stainless steel, and whether they are critical to the environment in which you are intending to work;

(1) Non-Corrosive

Stainless steel has non-corrosive properties making it suitable both for harsher environments where there may be exposure to environmental factors, such as near saltwater, and for the food and drink industry where corrosion can lead to cross-contamination due to surface pitting and damage. The latter can be particularly dangerous, considering the potentially life-threatening impact of cross-contamination to people suffering from food allergies.

(2) Spark-Proof

Stainless steel has non-sparking properties, meaning the risk of sparking, causing a fire or explosion, is mitigated. This is especially important for potentially hazardous or explosive atmospheres where flammable gases mix.

(3) Recyclable

Stainless steel has proven to be an extremely environmentally friendly material, being - in theory -100% recyclable. The main alloying elements are chromium, nickel, and molybdenum, which are all highly valuable and can be easily recovered and separated from other materials at the point of recycling.

(4) Long Service Life

Stainless steel carries a longer service life than regular steel due to its non-corrosive and rust proof properties, so whilst the initial outlay is higher, the attachment is likely to last longer, with its life often spanning several decades.

(5) Easy Cleaning

Due to its non-corrosive properties, stainless steel is particularly effective in industries where pressure washing and steam cleaning are necessary, such as the food and drink industry.

Conclusion

It’s not only important to choose the correct forklift attachment that best suits your material handling needs, but also to select the most suitable materials from which they’re made, bearing in mind the environment in which they will be used. Contact Attachments offer fully ATEX-certified attachments, all of which are CE marked and manufactured from spark-proof stainless steel suitable for use in hazardous, explosive, and corrosive environments.