Call Us +44 (0)1686 611200

Proudly Made in the United Kingdom

A Guide On When to Replace Your Forklift Attachments

April 06, 2023

As with any other piece of machinery and equipment in the workplace, forklift attachments need to be replaced every so often depending on its wear and tear. But exactly when is the right time? Our team shares what signs you should look out for…

How do you know when it’s time to replace your forklift attachment? We’ve gathered our expert team to share some of the signs that you’ll need to look out for to help you with purchasing a replacement.

Visible Fractures and Damage

Spotting visible fractures and damage is one of the most obvious ways in which you’ll know it’s right to look into either fixing or replacing your attachment. Fractures might occur after regular and high demand use of a particular piece of equipment over years and is typically no reflection of the quality of the attachment itself.

Deteriorated or Worn-Away Load Marking

Deteriorated or worn-away load markings on your forklift attachments may not be as obvious as visible breakages or fractures, so it’s key to keep checking on your load markings regularly to ensure they’re fit for purpose.

Unusual Noises During Operation

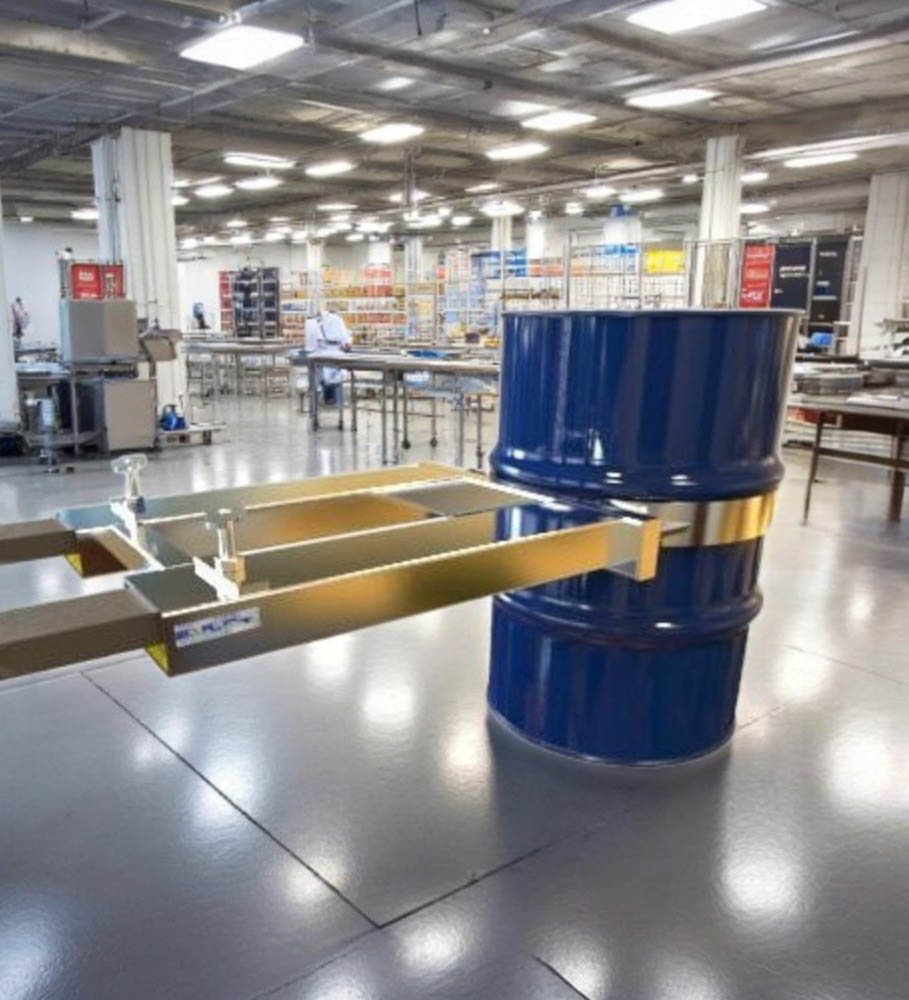

Aside from the physical wear and tear of equipment, you might notice a funny or unusual noise during the operation of your attachment (e.g. noise coming from the gearbox of a forklift drum rotating attachment). Anything that’s out of the ordinary should be a red flag to check your equipment, and if concerned, a thorough inspection should be done to ensure that everything is working as it should be.

Faulty Mechanisms

Another obvious sign that something isn’t quite right is when the equipment doesn't perform as expected. If you notice any unusual or faulty mechanisms which once worked fine, it’s likely the equipment has reached the end of its life (or at the very least, needs fast attention to ensure it works safely and as intended).

Corrosion

Corrosion can be caused by excessive use and exposure to the elements – which many forklift attachments often are, depending on the type of workplace in which it’s operated. As a result, it’s often the case that corrosion can occur with prolonged use, and whilst it may not be an immediate cause for concern, over time can absolutely impact the safety and useability of an attachment.

Conclusion

Carrying out regular Thorough Examinations of your forklift attachment will ensure that you can spot any potential issues early on and, if possible, have them fixed – much in the same way as a car’s MOT. But ignoring any tell-tale signs that it’s time to replace your attachment, whether it’s noise-related or physical damage, can cause major health and safety concerns in the workplace, plus increase risk of harm.

To find out more about replacing your attachments, or to find out how to book your next Thorough Examination, please do contact the team on our live chat – they’d be happy to help.