Call Us +44 (0)1686 611200

Proudly Made in the United Kingdom

5 Forklift Attachments Designed To Help Transport Unstable Loads

By Jason Cadman on November 30, 2022

Unstable loads are a major hazard in forklift operations, and it is important that forklift operators be aware of the hazards and take steps to mitigate the risks, such as by equipping the forklift with the right attachment for the task in hand. Here’s our lowdown on five attachments that are designed specifically for handling unstable loads, to help keep your operations running smoothly and efficiently, but above all, safely.

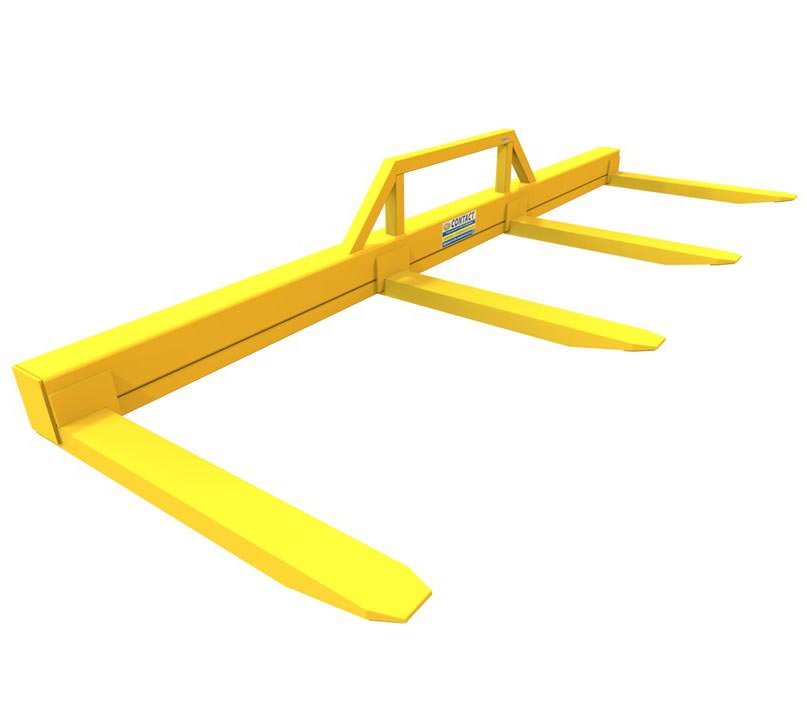

(1) Four Fork Attachment

Particularly in the construction industry, extra wide or awkward loads such as sheets of plasterboard or steel flats, or long products such as roofing beams, steel or plastic pipes, plastic extrusions, or timber, etc. can often present some manual handling challenges.

In these instances, wide load stabilising attachments such as the four fork attachment are the perfect forklift accessory of choice, utilising four forks to evenly spread and support the load being carried, providing that extra product stability and support required.

Manufactured to order to suit a specific application, four fork attachments can come with either fixed forks or adjustable forks for added versatility.

The forklift forks simply slide into the inner fork sleeves of the wide load stabiliser attachment, whilst the outer forks support and balance the load, also reducing the risk of product damage.

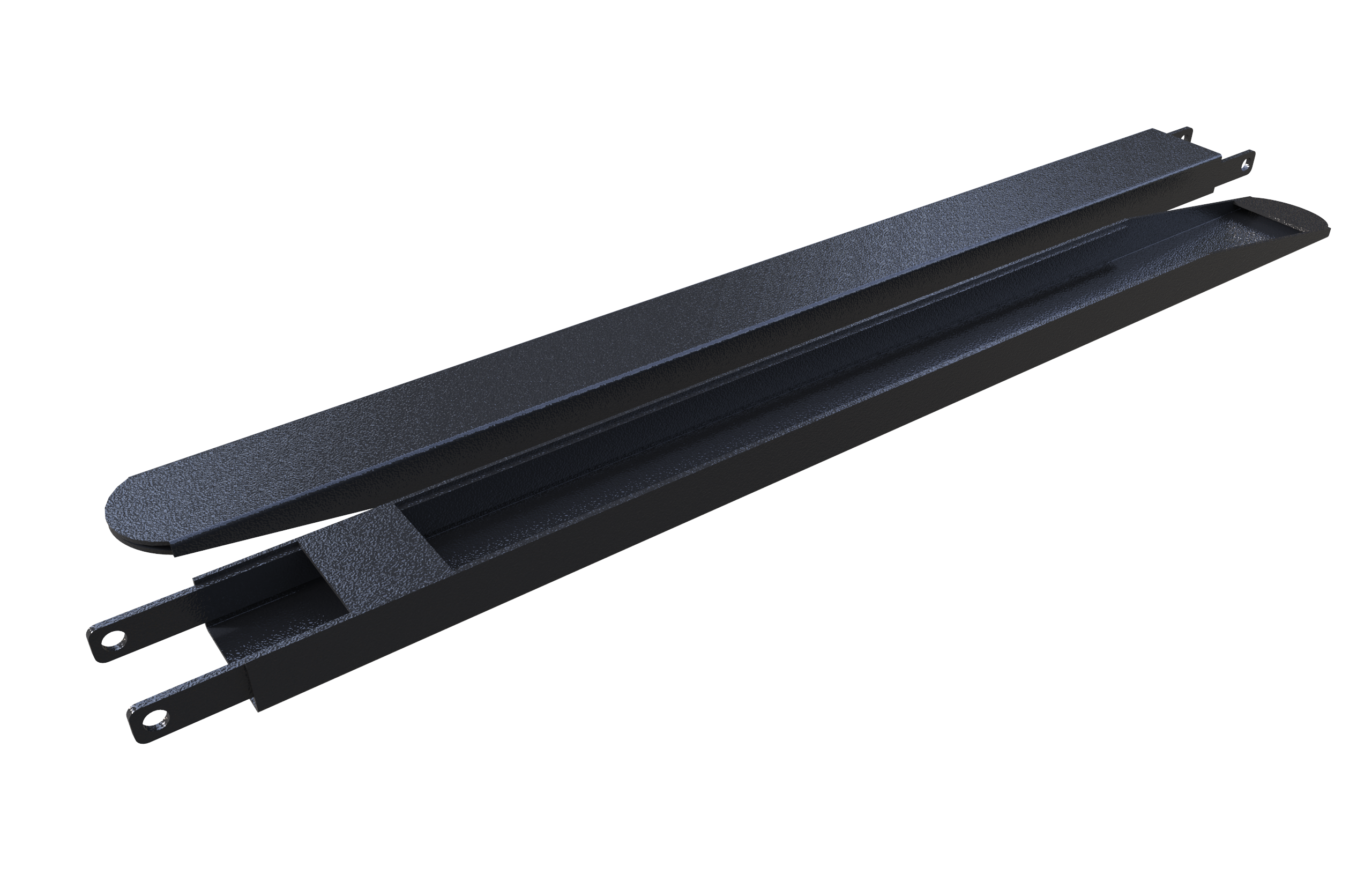

(2) Forklift Extensions

Forklift extensions are an ideal temporary solution when a longer reach or extra load stability is required. They offer safe and stable handling of loads that are longer than the forklift forks, whilst retaining the manoeuvrability of the lift truck for conventional operating.

Available both in heavy-duty and ultra-heavy-duty options, they offer a quick and simple add on designed to meet the rigors of everyday industry whilst making the task at hand both efficient and safe.

Removable heel pins ensure secure locking to the forks whilst also providing ‘drive in’ entry to negate the need for manual handling, keeping you compliant with manual handling regulations, and a plated folded channel design to the underside offers additional strengthening properties and ensures the extensions do not ride up the back of the fork.

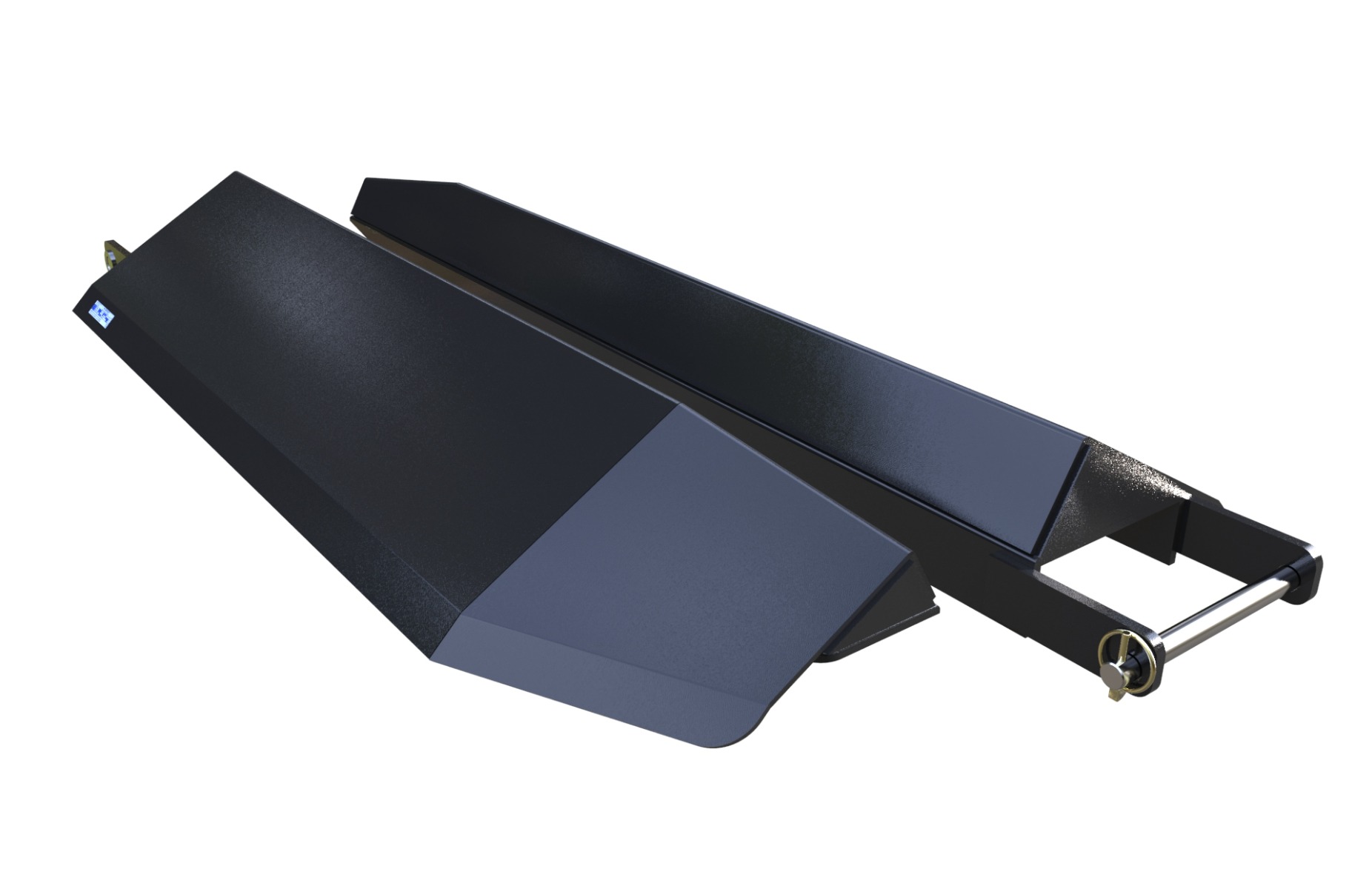

(3) Forklift Spreader Beam

Specifically designed to help safely handle particularly wide or long awkward loads, the spreader beam is an asset to all industries.

Easily fitted onto the forks of the lift truck with heel pin retention for safety, the forklift spreader beam can even be tailor-manufactured to any width and capacity to suit specific handling requirements, with lifting slings available if required.

Strong hooks & shackles ensure a combination of safety and efficiency, coupled with low maintenance costs and long service life, while large fork pockets make light work of switching from pallet handling to wide load handling saving time and money.

(4) Triangular Fork Sleeves

Offering all the same characteristics as heavy-duty fork extensions, these triangular fork sleeves come with the added feature of an angled face plate, providing the perfect solution for handling cylindrical loads on the forks such as paper reels, cable drums, etc.

The risk of such products rolling off the forks is mitigated, meaning you can manoeuvre such items safely and with confidence.

A fully formed profile toe with an end cap for added strength, and fixed retaining bars (or removable pin when sleeve length is greater than 2000mm), promptly and safely secures the fork sleeves to the truck forks.

(5) Forklift Boom

The low profile design of the forklift boom makes it well suited for handling rolls or coiled products that are stacked, for example, loading or unloading stacked rolls from a lorry, whilst giving the truck operator increased visibility.

An ideal solution for when time is at a premium, the fork-mounted design of the forklift boom with large fork pockets allows the truck operator a speedy fitment and changeover from pallet handling to roll handling with little downtime, keeping operations smooth and efficient.

Manufactured to order to ensure the correct boom diameter is supplied based on the combination of roll length and roll weight, giving peace of mind that the forklift boom will be fit for purpose.

The leading edge nose cone is designed to avoid damage to the roll being handled whilst offering easy 'glide in' pick up, and with both safety and longevity in mind, twin heel retaining pins ensure the forklift boom is securely fitted to forklift forks, whilst high-grade EN19T steel offers strong, durable, and long service life properties.

Attachment Safety Considerations

Now that you have chosen the perfect forklift attachment for handling your particular unstable load, there are a couple of safety factors you should consider to ensure the attachment you have in mind is perfectly suited for your handling needs.

Has A Risk Assessment Been Carried Out To Ensure Your Chosen Forklift Attachment Is Appropriate?

In every case, a proper risk assessment should be carried out to ensure the suitability of any new forklift attachment for its intended purpose.

Taking, for example, a four fork attachment which is designed for safe handling of wide unstable loads. Whilst it can reduce associated risks of doing just that, when an uneven surface is introduced, this can cause the product to slide off the attachment. It’s important to fully consider not only the intended task, but also the environment within which the attachment will operate.

Is Your Forklift Suitable For Handling Both The Combined Weight Of The Load And The Attachment?

It’s never a good idea to overload the lifting capacity of your host truck. But if the forklift attachment is rated with a higher lifting capacity than a truck can handle, it can become especially dangerous. Give careful consideration to the capacity ratings to avoid both safety risks and unnecessary wear and tear.

Ensure the forklift attachment is properly rated, paying close attention to how this affects your forklift truck’s safe handling capacity. This is known as the ‘De-Rated’ capacity and is affected by many factors such as the weight of the attachment, combined with the weight of the product to be handled, and the distance from the attachment to the forklift truck.

Conclusion

Whatever industry you work in, whether construction, logistics, or pharmaceutical, you have a duty of care to ensure that your attachment and all equipment used with your forklift truck are legal, fit for purpose, and above all, safe. For any questions about handling stable loads, please contact a member of the Contact Attachments team today.